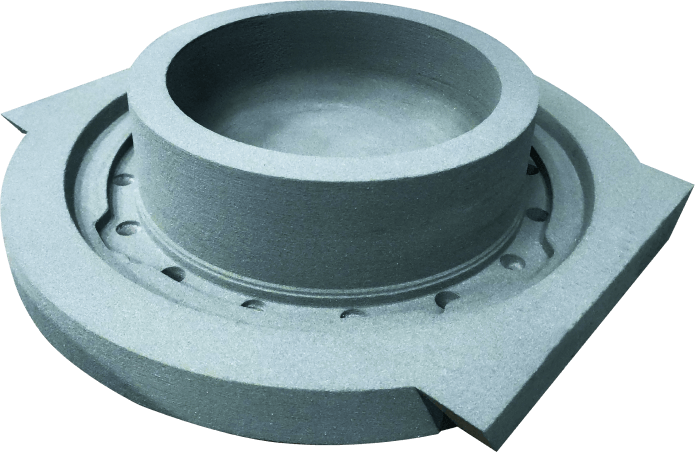

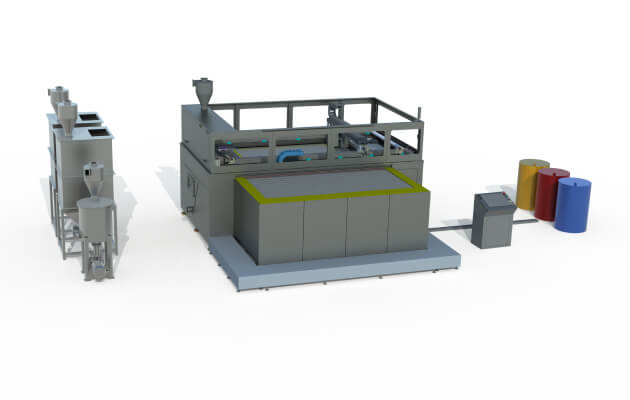

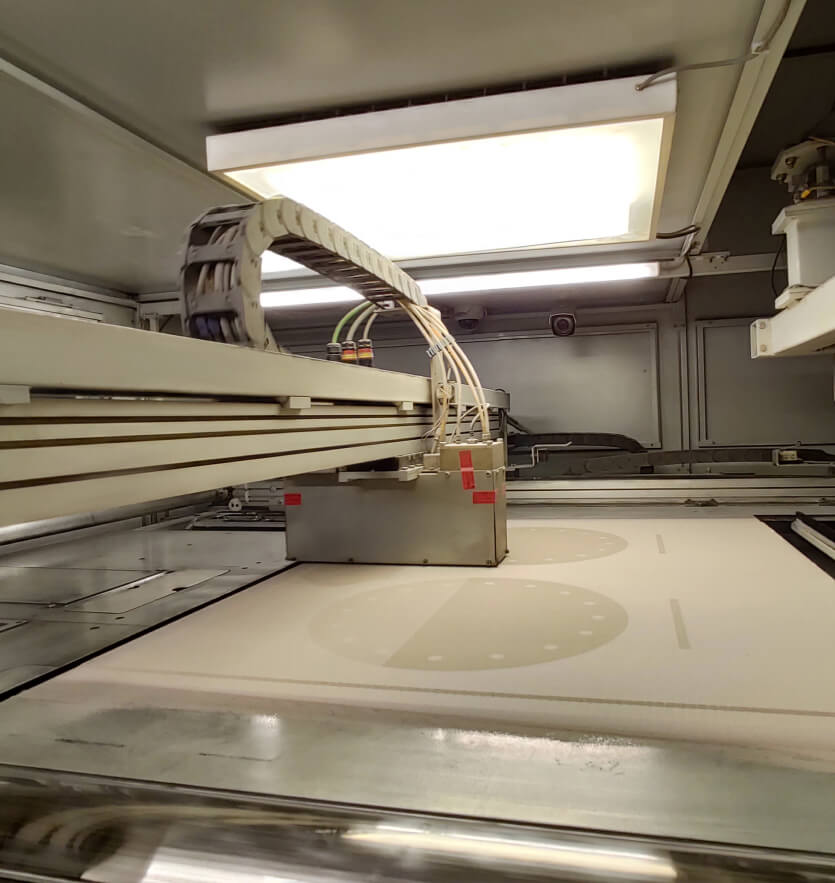

The technology allows producing casting molds of any configuration with high speed, accuracy, and reliability for casting ferrous and non-ferrous metal.

Compared with conventional production

-

2-3 days

Make a casting pattern

-

2 days

Molding of the casting pattern

-

1 day

Melt the casting pattern out

-

1 day

Baking the casting mold

-

1 day

Pour the metal

Manufacturing time 8 days

-

1 day

Download the CAD model and print it

-

1 day

Pour metal into casting mold

Manufacturing time 2 days

Submit a request to have a consultation, and we will contact you soon to answer all your questions.

Get a consultation

Affordable consumables for molds.

This reduces the cost of molds compared to molds made on similar equipment and guarantees prompt delivery of consumables.

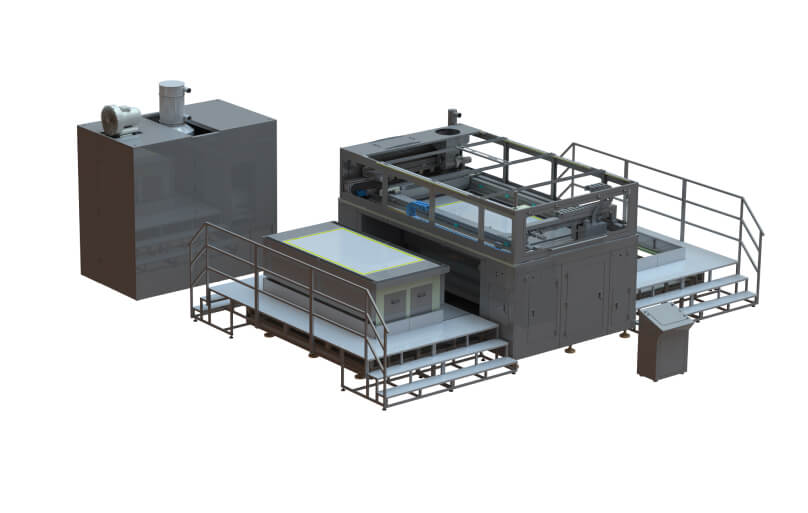

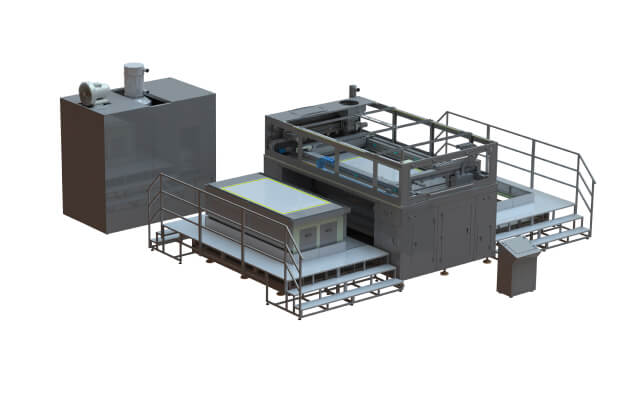

- We design and manufacture the equipment ourselves

- High quality and trouble-free operation of the equipment

- The software of own development

- Quick technical support

- Competitive prices providing quick return on investment and reduction of production costs

- Free supply / maintenance of equipment

- No external economic risks

- Available consumables for printing

- ZIAS Machinery is ready to modify 3D printers for the customers requirements